Home → Sublimation printing

Categories

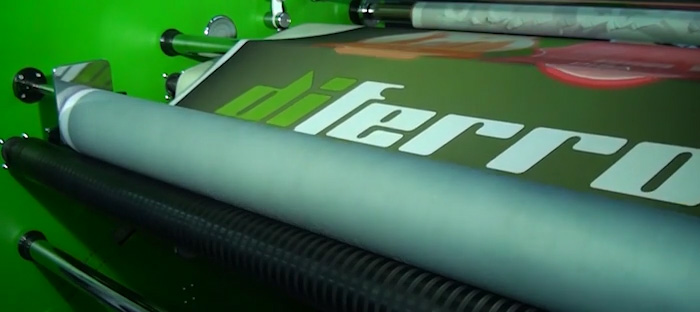

Sublimation printing

Sublimation printing is a specialized printing process in which the ink transitions directly from a solid to a gas state under heat, bypassing the liquid phase.

This process allows the ink to bond at a molecular level with the material being printed, resulting in durable and vibrant products.

| Quantity | Unit price |

|---|---|

| Minimum price | 15.8 EUR |

| 5 – 20 m² | 3.3 EUR / m² |

| 20 – 50 m² | 2.6 EUR / m² |

| 50 – 200 m² | 2.1 EUR / m² |

| 200 – 500 m² | 1.96 EUR / m² |

| More than 500 m² | 1.82 EUR / m² |

The file preparation cost is 1 EUR / graphic.

- The above prices include the cost of printing, and cutting to size. The prices are net prices and do not include VAT.

The sublimation printing process consists of the following steps:

- The design is printed onto transfer paper using a printer equipped with special sublimation ink.

- The printed paper is placed onto the material, and the design is transferred to the material using a heat press at high temperatures (around 200°C) and pressure.

- Under heat, the ink becomes a gas and embeds into the fibers of the material. Once cooled, it solidifies again, ensuring the design is permanently and wear-resistantly fixed.

Sublimation printing can produce a variety of products, such as:

- Clothing items: T-shirts, sportswear, caps

- Home decor items: Pillowcases, curtains, bedspreads

- Advertising materials: Flags, banners

- Corporate gifts: Mugs, mouse pads, keychains

- Fan merchandise: Scarves, seat cushions, drawstring bags

For sublimation printing, the material must contain at least 80% polyester to ensure proper ink adherence. Sublimation can only be performed on white materials because the ink does not have a coating layer, meaning colored materials would not display the desired colors accurately.

Advantages of Sublimation Printing:

- Excellent colorfastness and wear resistance.

- Vibrant and detailed colors.

- Flexible and soft final product that does not affect the material’s breathability.

- Cost-effective and quick process.

The maximum printing width for sublimation is 160 cm, while the maximum sublimation width on material is 156 cm.

Order Process:

- Submit order: Orders are submitted via email, including the production files.

- Payment: Pay the pro forma invoice.

- Production and shipping: We produce the requested material and ship the package.

For orders on supplied material, we request a sample piece of the fabric for test printing before the first print.

If needed, we also provide comprehensive sewing services to create the finished product from the printed material. This service is provided based on a custom quote, so please contact us via email at print@printandcut.hu for details.