Home → In archive admin

Categories

UV Transfer printing

New solution in the world of labeling and emblem making

UV Transfer technology, also known as UV DTF, offers a new solution in the world of labeling and emblem making, as it can be used on almost any kind of hard surface product.

| Quantity | Unit price |

|---|---|

| Minimum price (up to 0.5 m²) | 25 EUR |

| 0.5 – 5 m² | 36 EUR / m² |

| More than 5 m² | 29 EUR / m² |

The file preparation cost is 1 EUR / graphic.

- The above prices include the cost of materials, printing, and cutting to size. The prices are net prices and do not include VAT.

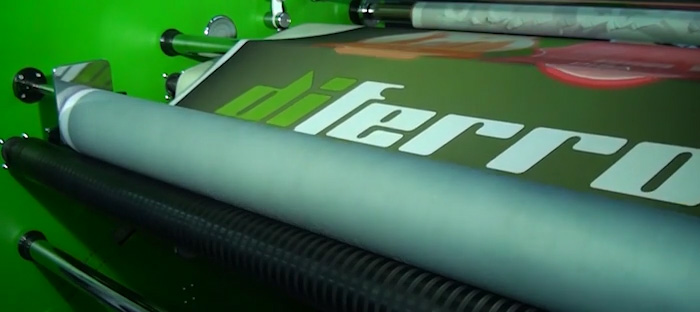

UV Transfer technology involves printing directly onto an adhesive film in a white, CMYK and varnish layer, the print then passes through a laminator, which is used to apply a film to aid application. With the prints thus made, there is nothing more to do than to cut them up and stick them on.

The application of UV Transfer stickers is extremely simple – no tools are required to apply (e.g. heat press, iron, etc.) just the cleaned surface product, the sticker and your hands. As a first step the UV Transfer sticker is peeled off the white film, then positioned, then, once properly adjusted, the sticker is firmly stitched on and the transparent film is peeled off. And there you have it, your fully customized product.

How is it different from an ordinary paper or vinyl sticker?

- UV Transfer stickers are also excellent for use on products with a dark surface.

- No special pre-treatment required of the surfaces to be labeled.

- There is no need for scoring or cutting.

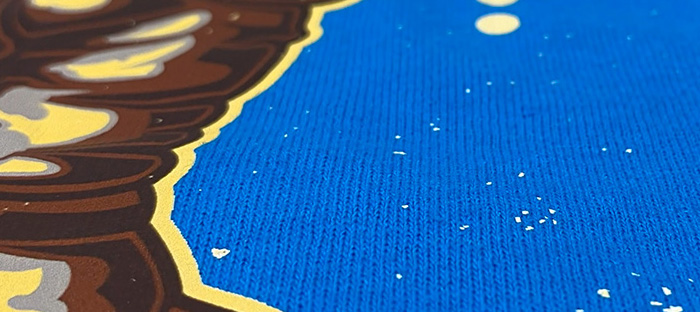

- Background-free, borderless designs can be produced, which are similar in quality to screen-printed designs.

- Thanks to the varnish layer, the surface of the UV Transfer sticker is glossy and has a nice 3D effect, giving a very sophisticated look.

Thanks to the advantages of UV Transfer technology and its easy of application, it is a great way to label advertising and promotional products.

A guide to material handover:

- Maximum print width: 58 cm

- Please submit the files to be printed in 300 dpi resolution, in CMYK color mode, transparent background, to scale TIFF format.

On our YouTube channel we also show you

some ideas of different usability ways of these stickers.

If you have any questions, feel free to contact us via e-mail!